Oversize lumps/chunks of agglomerated solids in industrial process streams often lead to system blockages that can interrupt processing, put excess stress on equipment, and lead to unscheduled downtime.

This downtime can be mitigated by breaking down oversized materials and eliminating the obstructions with crushing equipment, such as the ACC Flow-Sizer Crusher. This machine uses a rotating drum with blades to impact and break down any oversize chunks or lumps to a free-flowing size – keeping the process running smoothly and efficiently.

What is the Flow-Sizer Crusher?

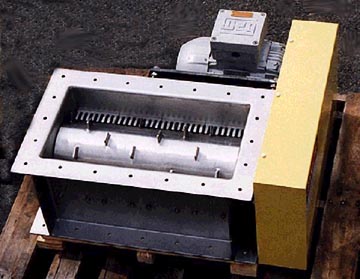

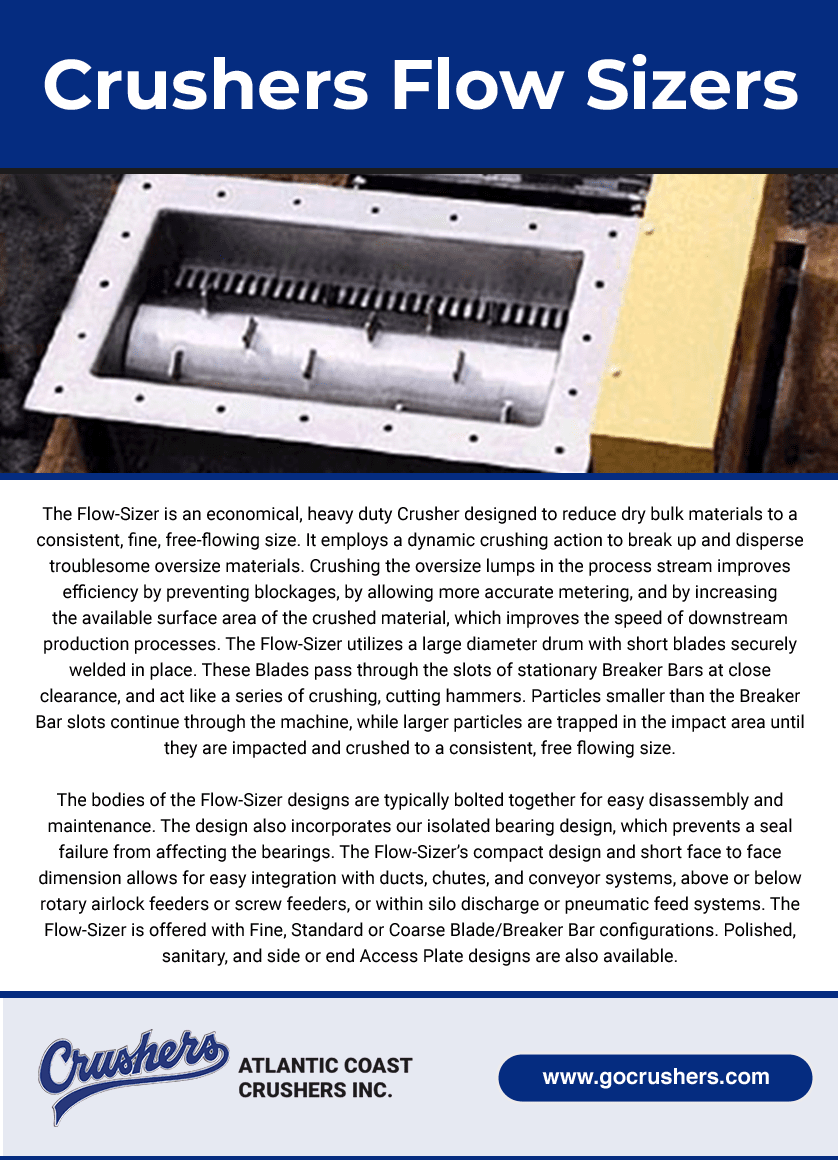

The Flow-Sizer is an economical, heavy-duty Crushing machine designed to break down dry, bulk materials to a fine, consistent, and free-flowing particle size.

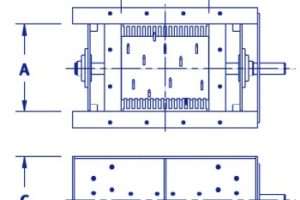

The Flow-Sizer are single shaft, and use a large diameter rotating drum with securely-welded short blades. These blades pass through the slots of a series of stationary Breaker Bars mounted to the inside walls of the machine at close clearance. The Breaker Bars prevent oversize materials from passing through the unit until the blades pass through, acting as a series of crushing, cutting hammers. Oversize lumps / chunks are impacted and broken down until they are small enough to pass through the slots and are a consistent, free-flowing size.

Flow-Sizers are very compact and have a short face-to-face dimension, allowing for easy integration with conveyor systems, chutes, ducts, above or below rotary airlock feeders or screw feeds, and within pneumatic feed or silo discharge systems.

The Flow-Sizer is offered with Course, Standard, or Fine Blade/Breaker Bar configurations.

Sanitary designs, with polished components and with Side or End Access Plates allowing for easy internal cleaning are also available.

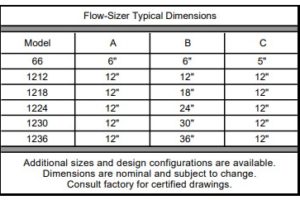

Common sizes for the Inlet/Outlet dimensions of the Flow Sizer range from 6” x 6”, up to 12”x30” or larger when needed.

Additional Benefits of a Flow-Sizer Crusher

Incorporating a Flow-Sizer Crusher into your processing operations can result in a number of additional benefits, including:

- Crushing oversized materials in the process stream, you can improve efficiency by increasing the surface area of the crushed materials, which allows for faster melting or other chemical reactions.

- Having a consistent and predictable particle size allows for more efficient and more accurate weight or volume metering. Accurate metering will enhances the speed of your downstream production processes.

- Having a small consistent feed size can reduce the wear and tear on downstream equipment such as conveyors, mixers, blenders, etc.

Why Partner With Atlantic Coast Crushers for Crushing Equipment?

At Atlantic Coast Crushers, we specialize in providing our clients with high-quality crushing equipment that’s designed to make batch processing and the transportation of free-flowing solids easier. We specialize in designing specialized tools and equipment that can crush, cut, and break down oversize solids into free flowing powders.

Our team of crushing and material experts will help you find the right crusher unit for your materials and production line.

If one of our existing units doesn’t fit your requirements, we’ll help design and build a customized Crusher to fit your specifications and application needs.

Contact Atlantic Coast Crushers Today for Crushing Equipment

Size Reduction / Crushing equipment can optimize your production process by reducing the risks of oversize materials causing obstructions and blockages by breaking them down to free-flowing, consistently-sized particles. Contact Atlantic Coast Crushers today to learn more about our Flow-Sizer Crushers and our other equipment and custom capabilities.