Flow Smasher™

The Flow Smasher Crusher is a heavy duty, high torque, high capacity crushing machine capable of reducing large chunks of friable bulk materials to a consistent and free-flowing size. Oversize lumps/chunks of agglomerated solids in industrial process streams often lead to system blockages that can interrupt processing, put excess stress on equipment, and lead to unscheduled downtime.

This downtime can be miinimized by breaking down oversized materials and eliminating the obstructions with the ACC Flow-Smasher Crusher. The Flow-Smasher employs one or more rotating Shafts with blades to impact and break oversize chunks or lumps to a free-flowing size – keeping the process running smoothly and efficiently. Crushing the oversize lumps in the process stream improves efficiency by preventing blockages, by allowing more accurate metering, and by increasing the available surface area of the crushed material which improves the speed of downstream production processes.

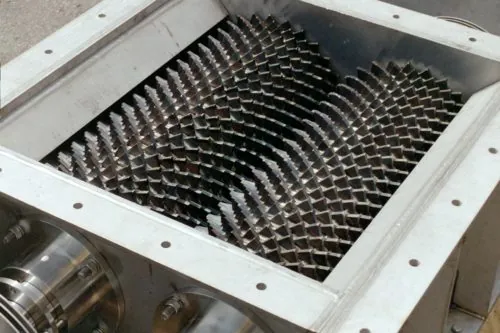

The most common Flow-Smasher design has a square or rectangular Body, with a sizing grid and two rotating Shafts with Blades. Particles smaller than the grid slots pass easily through the machine while any oversize materials are trapped within the impact area. The Shafts counter-rotate driving the oversize materials between the Shafts where the blades act like a series of crushing hammers, impacting and shattering the trapped chunks producing an output that is consistent and free-flowing. This shaft interaction enables the Flow-Smasher to break up larger, denser materials and, since the blade design is self- cleaning, it is often successfully used for problem materials that are sticky or tend to bridge.

The bodies of the Flow-Smasher designs are typically bolted together for easy disassembly and maintenance, and the design also incorporates our isolated bearing design, which prevents a seal failure from affecting the bearings. The Flow-Smasher designs are very compact, have a short face-to-face dimension. In addition the design allows for a variety of different Shaft and Blade configurations. Flow-Smashers are available with one, two, three, and even four Shafts when the product being broken apart is especially large. We also frequently use multiple stages of Crushers to break up very large chunks to a small particle size.

Common sizes for the Inlet/Outlet dimensions of the Flow-Smasher range from 12” x 12”, up to 48”x48” and larger when needed.

Hedgehog™, Brickbreaker™, and Bear-Claw™

The Hedgehog, Brickbreaker, and Bag Smasher designs are variations of the typical Flow-Smasher design, and have special Blade and drive configurations.

The Hedgehog has two intermeshing spiked rolls counter rotating at different speeds, and is designed to produce a fine output size at high volume. It also works well to tear long, thin boards, slabs, or tiles into small pieces.

The Brickbreaker design has two Shafts with high strength cutters arranged in an advancing spiral design. As the name suggests, the blade design of the Brick Breaker allows us to use a slow speed / high torque gear drive to break up large, very hard blocks of material.

The Bag Smasher design is similar to the typical Flow-Smasher with two Shafts, but uses hooked blades arranged in a special pattern that creates a “clam-shell” open/close action as the shafts rotate This blade action is designed for breaking down “slabs” of materials, for example solidified 50# bags of product.

The Flow-Smasher is also available in ACC’s patented “split body” design, which allows for remarkable flexibility in the design of sanitary construction, special blade arrangements, special inlet and outlet configurations, and extremely short face-to-face dimensions.

Lump breakers are a type of machinery used to process large materials by breaking them down into smaller materials. Each lump breaker unit has specially designed blades, which rotate through a fixed comb to efficiently crush and reduce the size of the material. By breaking up large clumps of material into small, more uniform particles, lump breakers improve downstream processing.

At Atlantic Coast Crushers, we specialize in creating effective machinery that can break down large potential obstructions into small solids. Our Flow-Smasher lump breaker can be integrated into your existing system, and it’s available in multiple different designs to fit your specific application or processing system.

What Is Flow-Smasher?

Flow Smasher crushers are heavy-duty, high torque, and high-capacity crushing machines capable of reducing large chunks of friable bulk materials to a consistent and free-flowing size. The machines employ a dynamic crushing action to break up and disperse troublesome materials. Crushing the oversized lumps in the process stream improves efficiency by preventing blockages, allowing more accurate metering, and increasing the available surface area of the crushed material, which improves the speed of downstream production processes.

Flow-Smasher Design

Typical Flow-Smasher designs use one or two rotating shafts with blades and a sizing grid with individually replaceable cross-bars. Particles smaller than the grid slots pass easily through the machine while any oversized materials are trapped within the impact area. The rotating blades, acting as a series of crushing hammers, impact and shatter the trapped chunks and produce an output that is consistent and free-flowing. Flow-Smashers with two shafts have counter-rotating blades. The counter-rotation draws the oversized material between the shafts, where it is impacted by both sets of blades. This enables the Flow-Smasher to break up larger, denser materials. Since the blade design is self-cleaning, it is often used for problem materials that are sticky or tend to bridge.

The bodies of the Flow-Smasher designs are typically bolted together for easy disassembly and maintenance. The design also incorporates our isolated bearing design, which prevents a seal failure from affecting the bearings. The Flow-Smasher is also available in ACC’s new patented “- 04” design. The “-04” design allows for remarkable flexibility in the design of new blade arrangements, special inlet and outlet configurations, and extremely short face-to-face dimensions. The Flow-Smasher designs are very compact, have exceptionally short face-to-face dimensions, and are available with a variety of motor and drive configurations that enable easy integration with ducts, chutes and conveyor systems, above or below rotary airlocks, silo discharges, or bulk bag unloaders.

We offer three effective Flow-Smashers that are designed to provide optimal tearing and crushing power for different applications. All three designs have a two-shaft construction but use different blade configurations.

Our designs include:

- Hedgehog™. This model is designed to process very high capacities of materials to a fine output size. It also works well to tear long/thin boards, slabs, or tiles into small pieces.

- Brickbreaker™. This design provides high levels of power and torque to break down large and hard materials.

- Bear-Claw™. Similar to the Brickbreaker™, this model features a distinctive design for reducing the size of large, hard blocks of material.

Benefits of Lump Breakers

Incorporating a Flow-Smasher Crusher into your processing operations can result in a number of additional benefits, including:

- Crushing oversized materials in the process stream, you can improve efficiency by increasing the surface area of the crushed materials, which allows for faster melting or other chemical reactions.

- Having a consistent and predictable particle size allows for more efficient and more accurate weight or volume metering. Accurate metering will enhances the speed of your downstream production processes.

Having a small consistent feed size can reduce the wear and tear on downstream equipment such as conveyors, mixers, blenders, etc.

Why Partner With Atlantic Coast Crushers for Lump Breakers?

At Atlantic Coast Crushers, we specialize in providing our clients with high-quality crushing equipment that’s designed to make batch processing and the transportation of free-flowing solids easier. We specialize in designing specialized tools and equipment that can crush, cut, and break down oversize solids into free flowing powders.

Our team of crushing and material experts will help you find the right crusher unit for your materials and production line.

If one of our existing units doesn’t fit your requirements, we’ll help design and build a customized Crusher to fit your specifications and application needs.

Contact Atlantic Coast Crushers Today for Crushing Equipment

Size Reduction / Crushing equipment can optimize your production process by reducing the risks of oversize materials causing obstructions and blockages by breaking them down to free-flowing, consistently-sized particles. Contact Atlantic Coast Crushers today to learn more about our Flow-Sizer Crushers and our other equipment and custom capabilities.